Energy Efficiency benefits of Waffle Pod Slab

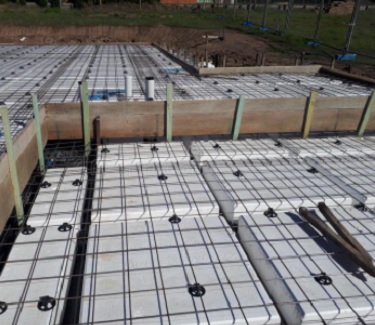

Waffle slab is mainly a cost-effective structural element used in the construction of buildings. It consists of edge footings and narrow internal strip footings. With waffle pod slab comes some energy cost-saving benefits. It is built on the ground and 170mm to 370mm polystyrene waffle pods fill the voids between the strips. The polystyrene in the waffle pods and air pockets built into them provides insulation to the floor. This improves the thermal resistance of the slab which can assist with Section J energy compliance, 6-star energy rating or other Alternative Solutions like JV3 or VURB. Also, as NatHERS tools take the thermal benefits of waffle pod slabs into account, BESS energy points could be obtained for ESD initiatives in Victoria having this floor construction.

What is the thermal benefit of a waffle pod slab for energy rating?

The use of an almost 200mm waffle pod and unventilated air pockets in it, provides an insulating effect under the building floor. In heating dominant buildings, the extra insulation effect of the waffle pod slab assists with better energy compliance of the building at lower construction cost.

While performing VURB as an Alternative Solution, the benefits are even greater. NCC requires the reference building to have a conventional concrete slab, whilst the proposed building can benefit from the waffle pod slab saving on heating demand. This allows for cheaper glazing costs, especially in cold regions.

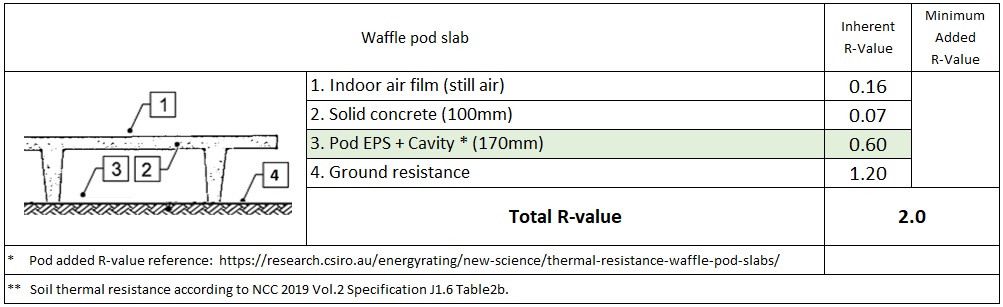

For Section J energy reports, BCA requires concrete slabs to have at least R2.0. As soil thermal resistance contributes to the floor Total R-value, small buildings with a low area to perimeter ratio may have difficulties complying with the code. In these cases, the selection of waffle pod slabs may be enough for Section J compliance; or, other compliance methods like JV2, JV3 or NABERS must be undertaken.

What is the disadvantage of a waffle pod slab for energy efficiency?

The addition of insulation by waffle pods disconnects the ground thermal mass from concrete thermal mass. Compared to outdoor air, ground temperature experiences less fluctuation throughout the year.

In hot climates, the use of waffle pod slabs has a disadvantage as the added pod insulation blocks the heat transfer to the soil. This deprives the daytime conditioned zones of the ability to cool down during summer.

In cold climates, where the north-facing glazing area is high, the high thermal mass of concrete slabs stores heat in the day and lets it out in the night. The waffle pod slab connection to the ground is weak compared to the conventional slabs. Having low thermal mass, waffle slabs relatively lacks the heat storage ability, It also disrupts the free flow of heat from the slab to the building.

However, the benefit of the added insulation may greatly offset the disadvantage of low thermal mass in colder climates. The overall impact on the energy efficiency will have to be assessed using energy modelling (e.g. VURB Performance Solution or JV3 modelling).

It is worth noting that following a residential DTS pathway of energy compliance, thermal benefits of waffle pod slabs are not taken into account by the NCC as no insulation is required for concrete slabs on ground.

What is the equivalent R-value of waffle pods?

Referring to the research by CSIRO, the following insulation values are recommended for the waffle pod slabs:

- Waffle pod height: 170mm – R0.57

- Waffle pod height: 230mm – R0.6

- Waffle pod height: 300mm – R0.63

- Waffle pod height: 370mm – R0.65

Note that in the above, the waffle pod is assumed to be composed of 50mm polystyrene layers and an un-ventilated air pocket. Note that increasing the waffle pod height doesn’t add much to the insulation effect. Double the waffle pod height increases the added insulation value of the waffle pod by 14%.

The waffle pod slabs may be modelled by using a concrete top layer at the specified concrete thickness of the waffle pod slab system with an additional insulation layer of R0.57, R0.60, R0.63 and R0.65 for the 170mm, 230mm, 300mm and 370mm pod heights between the concrete top layer and the ground.

The following shows an example of a waffle pod in one of our Energy Compliance reports:

Why do waffle pod slabs fail?

Aside from energy-related pros and cons, the construction of waffle pod slabs may be tricky in some specific locations. Construction of waffle pods are deemed to comply with AS2870 – The Australian Standard for Residential Slabs and Footings. Poor design or construction of waffle pods in regions with a high risk of cyclones or tornados may cause slab uplift and wall cracks. Also, the construction of waffle pod slabs is not a good idea where the landscape has a high slope or has a soft ground condition. The use of conventional slabs is better in these circumstances.