What insulation do I need?

Whether you need to reduce your gas or electricity bills, get a building permit or increase the energy efficiency of your house, you need to know something about insulating materials. So what are your options? does it fit? is it enough? is it fire-resistant or not? here, we try to find out answers to these questions.

What type of insulation do I need?

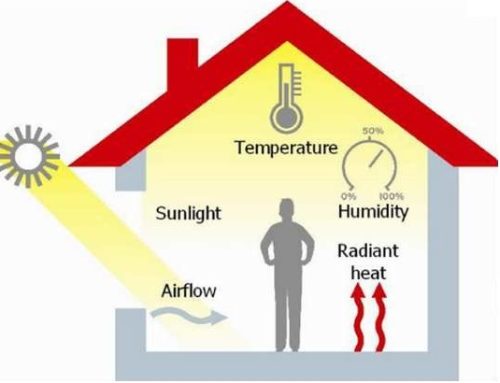

Where you have a difference in temperature between two sides of an object, heat transfers from one side to the other. To significantly reduce the amount of heat transfer, you need a material with a very low thermal conductivity, that is insulation. With respect to the mechanics of heat transfer, there are two types of insulation:

- Non-reflective insulation reduces the conduction heat transfer. Trapped bubbles of air make it difficult for the heat to pass through.

- Reflective insulation reduces the radiation heat transfer. Very bright and low-emissive surfaces reflect the heat.

When you are conducting an energy report following the DTS compliance pathways, Verification Methods or combination of the two, you need to know what type of insulation you must be looking for and how much insulation you need to reach a certain R-value. There are seven major types of insulation that must be selected in accordance with your need. Here, we try to summarise it.

| Type | Insulating material | Application | Note | |

|---|---|---|---|---|

| Batts & rolls | Fibreglass Rockwool | Between stud framing walls Between floor joists Between ceiling joists Between roof purlins/rafters Beneath metal roof cladding. | Available, low-cost and easy to install. This insulation is associated with thermal bridging. Insulation batts have a relatively low R-value per unit of thickness. Comes in specific sizes and thus may require compression to fit which reduces R-value. Ranges from R0.6 to R2.7 for stud walls, R1.0 to R4.0 as roof blankets, and from R1.5 to R7.0 for ceilings or floors. |

| Rigid insulation | Polystyrene Polyurethane | Concrete walls Cavity masonry walls (inside the cavity) Concrete slabs on ground Concrete roofs Suspended concrete floors/ceilings | This insulation comes in many sizes and thicknesses. Very effective in terms of R-value per thickness. Associated with very little to no thermal bridging. Water-resistant and vapour-permeable. It is not used for existing buildings renovation and retrofits. Relatively high-cost. Some products include attached lining like insulated plasterboards Ranges from R1.0 to R4.5. Not very common to be installed between timber or metal frames. |

| Insulated Concrete Form (ICF) | Polystyrene | New wall construction | Two layers of polystyrene board with air or concrete-filled cavity. Can bear heavy loads. Associated with very little to no thermal bridging. Very high R-values up to R3.5. Very efficient noise isolation. Sensitive to water as the steel webbing is not water-resistant. Very high cost. One of the possible solutions for Class 3, Class 9a and Class 9c buildings in certain climate zones in Australia. |

| Autoclaved Aerated concrete block | Concrete block filled with bubbles of air | New wall construction | Aerated concrete blocks consist of solid materials like quartz sand and cement and up to 80% air. Eco-friendly and suitable to use for a Green Star Rating. or SDA/SMP projects. Lightweight and suited in locations with a high risk of earthquakes. Easy to transport, easy to install and thus low labour cost. Fire-resistant with high compressive strength. Brittle nature and may crack upon impacts or thick screw fixing. Ranges from R0.4 (100mm dense) to R3.0 (300mm lightweight). If the required Total R-value is high, thick blocks are required. Not suitable in humid regions. |

| Blown-in insulation | Fibreglass Cellulose Rockwool | Blown into new or existing cavity walls Between new or existing stud framing walls Between new or existing ceiling/floor joists | Good energy efficiency solutions for existing buildings or alteration/extension projects. Fills the cavity in the existing double masonry walls with no destruction. Can be made of waste materials and thus could be eco-friendly. The best solution for insulating existing pipes and ducts without destruction. Ranges from R1.3 (50mm cavity) to R2.6 (100mm cavity) Very sensitive to mold if not sealed from outdoor conditions. |

| Sprayed foam insulation | Polyurethane Polyisocyanurate | Between new or existing stud framing walls Between new or existing ceiling/floor joists | Comes in two forms of open-cell (less dense – filled with air) and closed-cell (denser – filled with gas). Best energy efficiency solutions for the existing buildings. Seals all air gaps and existing building hacks and cracks. Doesn’t require a vapour barrier (especially in closed-cell type). Fills around obstacles with irregular shapes. The best solution for insulating existing pipes and ducts without destruction. Ranges from R2.25 (90mm open-cell) to R3.75 (90mm closed-cell) Very high-cost and requires an expert with safety training. |

| Structural Insulated Panels (SIPs) | Polystyrene | Pre-structured rooms SIPs built homes | A layer of insulation sandwiched between Oriented Strand Boards (OSB). Associated with no thermal bridging. The best solution for cool/cold rooms and Green Star Rating. Highest R-values. Ranges from R1.2 to R6.0 High-cost and can’t be used for existing/alteration works. Sensitive to pests and insects. |

| Reflective insulation | Reflective surfaces: Foil-faced Polyethylene bubbles Plastic film | External side of wall studs Underside of rafters/joists | Unlike other types of insulation, no specific R-value could be specified. Reflective insulation R-value depends on heat direction, emissivity and air gap. Low cost but not as effective as other types of insulation. Suitable for factories or warehouses. An air gap is required for reflective insulation to work effectively. Suitable for downward heat flow (roofs in climate zones 1 to 5). |

Thermal properties of different insulating materials

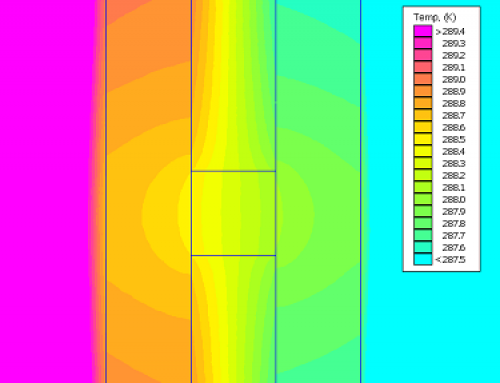

Thermal conductivity is defined as the amount of heat (in watts) transferred through one square metre (m2) of an insulating material (or any other material) of a given thickness (in metres) due to a difference in temperature. The lower the thermal conductivity of the material the greater the material’s ability to resist heat transfer, and thus the higher its thermal resistance (R-value).

| Material | Thermal conductivity (W/m.K) | Vapour Permeable |

|

|---|---|---|---|

| Cellulose fibre | 0.04 | Yes | No |

| Fibreglass | 0.057 (7 kg/m3) 0.044 (12 kg/m3) | Yes | Yes |

| Polyethylene foam | 0.04 | No | No |

| Polyester | 0.063 (8 kg/m3) 0.045 (16 kg/m3) | No | Yes |

| Expanded Polystyrene (EPS) | 0.039 | No | No |

| Extruded Polystyrene (XPS) | 0.028 | No | No |

| Polyurethane foam | 0.028 | Yes | No |

| Rockwool (blown-in) | 0.04 | Yes | Yes |

| Rockwool batt | 0.033 | Yes | Yes |

The thermal conductivity of the above materials is extracted from the FirstRate-5 manual for Star Rating, Table 9.

How to calculate insulation R-value?

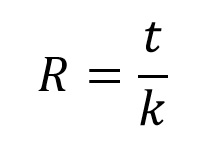

In order to calculate the insulation R-value, you need to have two parameters: thickness & thermal conductivity (see above).

Insulation R-value can be calculated as follows:

Where R is the insulation R-value (m2.K/W), t represents insulation thickness (m) and k represents thermal conductivity (W/m.K) and can be extracted from the table above.

For example, 50mm Rockwool batt with thermal conductivity of 0.033 W/m.K gives you R1.5 (R=0.05/0.033=1.5).

Note that the thermal conductivity of an insulating material depends on its density. Also, the temperature difference between the two sides of the insulation has a minor effect on its thermal conductivity; Therefore, it is wise to have the manufacturer’s data sheet and look for the correct conditions.

Minimum insulation requirements for commercial buildings in Australia

Australian Building Codes Board (ABCB) sets the minimum Total R-values for different parts of buildings. These minimum Total R-values depend on the climate zone, type of building and construction. Based on the Building Class, these values can be extracted from:

- NCC Volume 1: Class 2 (common area), Class 3, Class 5, Class 6, Class 7, Class 8, Class 9.

- NCC Volume 2: Class 1 and Class 10.

Based on NCC Vol 1.0 Section J DTS provisions and Energy Compliance Consultants past experience, the required insulation to comply with the code is presented below:

How to achieve R3.7 for roof?

The minimum Total R-value of a roof in climate zone 7 is R3.7. Following constructions achieve R3.7 (inclusive of thermal bridging effect) and more:

- Pitched metal roof and flat ceiling with 10mm plasterboard finish:

Bulk insulation between 90×45@900 c/c timber joists: R4.0 (R3.0 with reflective insulation)

Bulk insulation between 90×45@600 c/c timber joists: R4.5 (R3.5 with reflective insulation)

Bulk insulation between 140×35@900 c/c timber joists: R3.5 (R3.0 with reflective insulation)

Bulk insulation between 140×35@600 c/c timber joists: R4.0 (R3.0 with reflective insulation)

- Pitched metal roof and cathedral ceiling with 10mm plasterboard finish:

Bulk insulation between 140×35@600 c/c timber rafters: R4.0 (R3.5 with reflective insulation)

Bulk insulation between 140×35@450 c/c timber rafters: R4.0 (R3.5 with reflective insulation)

Bulk insulation between 190×45@600 c/c timber rafters: R4.0 (R3.5 with reflective insulation)

Bulk insulation between 190×45@450 c/c timber rafters: R4.0 (R3.5 with reflective insulation)

Bulk insulation between 203x79x1.9@1200 c/c metal rafters: R5.0 + reflective insulation + R0.2 thermal breaks

- Flat metal roof and flat ceiling with 10mm plasterboard finish:

Bulk insulation between 140×35@600 c/c timber rafters: R4.0 (R3.5 with reflective insulation)

Bulk insulation between 140×35@450 c/c timber rafters: R4.0 (R3.5 with reflective insulation)

Bulk insulation between 190×45@600 c/c timber rafters: R4.0 (R3.5 with reflective insulation)

Bulk insulation between 190×45@450 c/c timber rafters: R4.0 (R3.5 with reflective insulation)

Bulk insulation between 203x79x1.9@1200 c/c metal rafters: R5.0 + reflective insulation + R0.25 thermal breaks

- Flat concrete roof and flat ceiling with 10mm plasterboard finish:

Rigid insulation directly attached to the 100mm concrete roof: R3.5

How to achieve R1.4 for walls?

The minimum Total R-value of a wall in climate zone 2-8 for building classes 5 to 9b is R1.4. Following constructions achieve R1.4 (inclusive of thermal bridging effect) and more:

- External stud walls with metal cladding and 10mm plasterboard finish:

Bulk insulation between 90×45@450mm c/c timber studs: R1.2

Bulk insulation between 92×33.5×0.75@600mm c/c metal frames: R1.5 + 0.2 thermal breaks

Bulk insulation between 92×33.5×0.75@600mm c/c metal frames: R1.5 + Reflective insulation (inner) - External stud walls with 9mm fibre cement sheet and 10mm plasterboard finish:

Bulk insulation between 90×45@450mm c/c timber studs: R1.2

Bulk insulation between 92×33.5×0.75@600mm c/c metal frames: R1.5 + 0.2 thermal breaks

Bulk insulation between 92×33.5×0.75@600mm c/c metal frames: Double reflective insulation + R0.2 thermal breaks - External brick veneer walls (110m) and 10mm plasterboard finish:

Bulk insulation between 90×45@450mm c/c timber studs: R1.0

Bulk insulation between 92×33.5×0.75@600mm c/c metal frames: R1.5 + 0.2 thermal breaks

- External brick cavity walls (2x110mm):

>25mm cavity: R1.0 closed-cell rigid board

>40mm cavity: R1.0 blown-in insulation - External concrete wall (100mm):

Bulk insulation between 70×45@450mm timber studs: R1.2 (+10mm plasterboard)

Rigid insulation attached to the external side: R1.2 (no internal finish)

How to achieve R2.8 for walls?

The minimum Total R-value of a wall in climate zone 4,6 & 7 for building classes 3, 9a & 9c (ward area) is R2.8. Following constructions achieve R2.8 (inclusive of thermal bridging effect) and more:

- External stud walls and 10mm plasterboard finish:

Bulk insulation between 90×45@450mm c/c timber studs: R2.7 + Reflective insulation (inner e=0.05 + 20mm spacer)

Bulk insulation between 92×33.5×0.75@600mm c/c metal frames: R2.7 + R0.5 thermal breaks + Reflective insulation (outer e=0.2)

- External brick cavity walls (2x110mm):

>25mm cavity: unable to achieve, Performance Solution required.

>40mm cavity: unable to achieve, Performance Solution required. - External concrete wall (100mm):

Bulk insulation between 90×45@450mm timber studs: R2.7 + R0.2 thermal breaks + Reflective insulation (inner e=0.05)

Bulk insulation between 90×45@600mm timber studs: R2.7 + R0.4 thermal breaks (+10mm plasterboard)

Bulk insulation between 92×33.5×0.75@600mm metal frames: R2.7 + R0.5 thermal breaks + Reflective insulation (inner e=0.05)

Rigid insulation attached to the external side: R2.6 (no internal finish)

- Insulated concrete form (ICF):

150mm concrete sandwiched between EPS insulation (2x50mm) + 5mm render (exterior) and 10mm plasterboard (interior) finish

Wall: how to achieve R3.3 for walls?

The minimum Total R-value of a wall in climate zone 1 & 3 for building classes 3, 9a & 9c (ward area) is R3.3. Following constructions achieve R3.3 (inclusive of thermal bridging effect) and more:

- External stud walls and 10mm plasterboard finish:

Bulk insulation between 90×45@450mm c/c timber studs: unable to achieve, Performance Solution required.

Bulk insulation between 92×33.5×0.75@600mm c/c metal frames: unable to achieve, Performance Solution required.

- External brick cavity walls (2x110mm):

>25mm cavity: unable to achieve, Performance Solution required.

>40mm cavity: unable to achieve, Performance Solution required. - External concrete wall (100mm):

Bulk insulation between 90×45@450mm timber studs: unable to achieve, Performance Solution required.

Bulk insulation between 90×45@600mm timber studs: R2.7 + R0.5 thermal breaks (+10mm plasterboard) + Reflective insulation (inner e=0.05)

Bulk insulation between 92×33.5×0.75@600mm metal frames: unable to achieve, Performance Solution required.

Rigid insulation attached to the external side: R3.2 (no internal finish)

- Structural Insulated Panel (SIP):

150mm panel.