What Is VURB?

VURB (Verification Using a Reference Building) demonstrates compliance with residential energy provisions of the National Construction Code (NCC) by verifying that your proposed building with your preferred insulation and glazing uses less heating and cooling energy than the NCC Reference building. It allows for utmost flexibility by using hour-by-hour energy modelling software and results in reducing construction costs (e.g. glazing) compared with the NatHERS Rating or Deemed to Satisfy method. Find out on this page:

Who benefits from the VURB method for energy compliance?

What do I need? VURB or NatHERS Star Rating?

What are the pros and cons of the VURB method?

Frequently Asked Questions (FAQ)

Verification Using a Reference Building (VURB)

If you want to minimize construction costs related to energy efficiency, i.e. glazing or slab insulation costs, the best approach for NCC energy compliance is called Verification Using a Reference Building (VURB) method. This method allows for a more realistic building modelling and takes everything into account. This is where an assessor can optimize the shading, introduce shading devices, trade-off insulation and SHGC of the windows to conduct the best low-cost solution possible for your building.

VURB method is also the last resort for energy compliance of alteration or extension to an existing building; Especially where some parts of the building are to be kept from new works.

At Energy Compliance Consultants, we offer all avenues to demonstrate your building compliance under any conditions.

At Energy Compliance, we offer all avenues to demonstrate your building compliance under any conditions.

Quality

We perform more iterations to reduce your construction costs.

We illustrate the added insulation to minimize any mistakes during the construction stage.

Quality

We perform more iterations to reduce your construction costs.

We illustrate the added insulation to minimize any mistakes during the construction stage.

Service Guarantee

If we can’t reduce your construction cost by more than our fee, we’ll only charge our 40% deposit. This is the best proof of how cost-efficient our performance-based solutions are. You won’t get this anywhere else!

Quick Turnaround

Quotations: Same business day of inquiry.

VURB Performance Solution reports: 3-7 business days.

Quick Turnaround

Quotations: Same business day of inquiry.

VURB Performance Solution reports: 4-7 business days.

Who Benefits From VURB Method?

VURB method shows promise where:

A costly 6-star rating seems out of reach for alteration to an existing building or a new luxury house with high raked ceilings and large windows.

For an alteration or extension project, where some parts of an existing building are to be kept from new works while aiming for energy compliance.

You are seeking to optimize construction cost and energy use, having an experienced energy assessor by your side.

Additional insulation to some parts of a new building is impossible and you need an insulation trade-off.

Glazing cost is too high and you need to offset energy use by adding more insulation, optimized shading or shading devices.

You wish to kill a bird with one stone: having the best solution for compliance while using its realistic outputs for choosing the best energy source option.

Too Good To Be True?

How do we do VURB here at Energy Compliance Consultants?

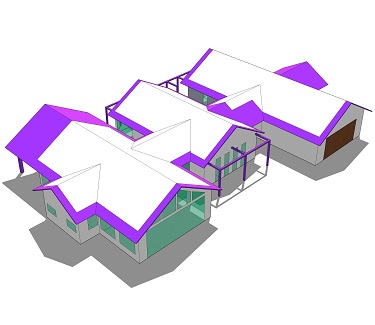

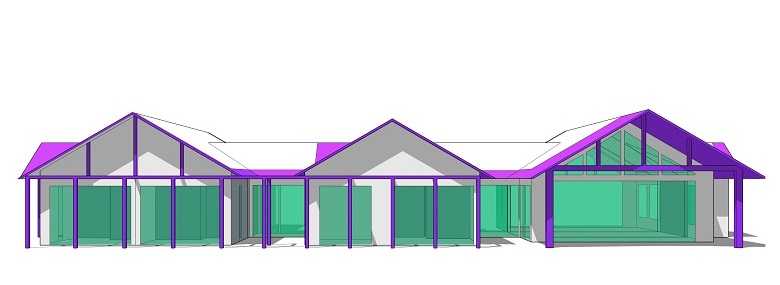

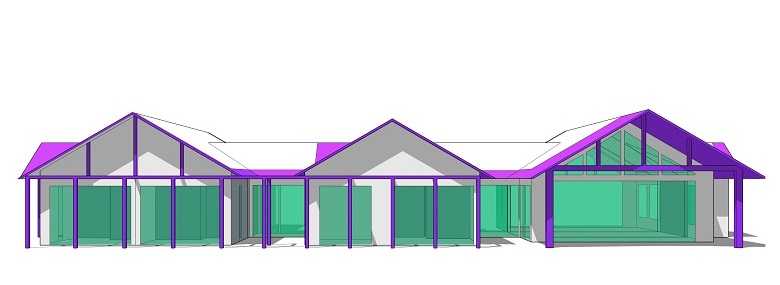

1. Model the geometry of the house as per final architectural plans

2. Apply heating and cooling setpoints and heat gains as specified in NCC.

3. Apply schedules for people, appliances and HVAC operation.

4. Use NCC Glazing Calculator to calculate minimum requirements for the glazing and assign them.

5. Apply minimum DtS insulation requirements to the building fabric. Save the model “Proposed building based on DtS requirements”.

– Ceilings not higher than 2.4m.

– Roofs pitched at 23 degrees with no skylights.

– Concrete slab on ground.

6. Apply the above facts to step 5 and call it “Reference Building”. Run the model and calculate annual heating and cooling demand.

7. Minimize the building cost for the “Proposed Building”. We may do this with low-cost thermal improvements such as adding insulation to the model from Step 5. Other low-cost means are shading size optimization or addition of shading devices to offset summer heat gains. If glazing cost is not the biggest concern, modify the cost minimization strategy. Addition of insulation to other parts of the building can reduce the high-cost added insulation to the existing walls.

8. Run the Proposed Building. The Proposed Building is deemed compliant if its heating and/or cooling demand is less than the Reference Building.

9. Iterate & optimize improvement to the Proposed Building in step 8 until you get to the sweet spot that offers the highest cost-saving.

10. Complete the report.

Too Good To Be True?

How do we do VURB here at Energy Compliance?

- Model the geometry of the house as per final architectural plans

- Apply heating and cooling setpoints and heat gains as specified in NCC.

- Apply schedules for people, appliances and HVAC operation.

- Use NCC Glazing Calculator to calculate minimum requirements for the glazing and assign them.

- Apply minimum DtS insulation requirements to the building fabric. Save the model “Proposed building based on DtS requirements”.

- FACT: NCC 2019 assumes an efficient standard Australian house should have:

– Ceilings not higher than 2.4m.

– Roofs pitched at 23 degrees with no skylights.

– Concrete slab on ground.

Apply the above facts to step 5 and call it “Reference Building”. Run the model and calculate annual heating and cooling demand. - Minimize the building cost for the “Proposed Building”. We may do this with low-cost thermal improvements such as adding insulation to the model from Step 5. Other low-cost means are shading size optimization or addition of shading devices to offset summer heat gains. If glazing cost is not the biggest concern, modify the cost minimization strategy. Addition of insulation to other parts of the building can reduce the high-cost added insulation to the existing walls.

- Run the Proposed Building. The Proposed Building is deemed compliant if its heating and/or cooling demand is less than the Reference Building.

- Iterate & optimize improvement to the Proposed Building in step 8 until you get to the sweet spot that offers the highest cost-saving.

- Complete the report.

Do I need VURB or Star Rating?

Whenever you are building a new residential dwelling or undertaking a major extension or alteration to your existing house, you’ll have to obtain a building permit from your governing council. In the process, you may come upon some difficulties regarding energy efficiency compliance for your development. Difficulties emerge from the high cost of building insulation and/or glazing to comply with the code. This includes, for instance, installing double or triple glazed windows or adding insulation to an existing wall.

So how do you overcome this problem? or in a better sense, how could you get your building permit while reasonably reducing your construction costs? VURB is a method proposed by NCC Vol 2.0 as a Performance Solution method of compliance that may suit your project condition.

Can you use VURB for commercial buildings?

Yes, and No! VURB is a term NCC uses as an alternative solution for residential buildings (Class 1 buildings to be more accurate). For commercial buildings, NCC refers to an alternative solution called JV3 modelling which is similar to VURB with fewer restrictions and easier compliance.

Click here for more information on NCC building classes.

What are all options to an NCC energy compliance for a residential building?

There are three ways to demonstrate energy compliance for your residential building:

- Elemental provisions: there exists a set of prescriptive provisions for insulation of building fabric, glazing thermal performance, building sealing and air movement. The only drawback of this approach is that it is very rigid; therefore, you cannot change any of the required provisions. This approach is generally called DtS elemental provisions.

- Star rating: this method is another DtS method of demonstrating compliance for energy efficiency under NCC. This method considers a building is deemed to comply with NCC energy efficiency provisions, provided the building obtains at least 6 stars from one of the NatHERS accredited tools.

CONs of above DtS approaches: The outputs of the above DtS approaches are proved to increase the cost of construction. This is certainly true for buildings with large floor areas or a large ratio of glazing to floor areas.

- Verification Using a Reference Building (VURB): this method allows for a more realistic energy modelling of a building. The energy assessor undertakes VURB through an energy modelling software capable of analyzing the energy demand of the house in an hourly manner. Due to this hourly analysis and the various realistic inputs from the actual house, the results of this method (if done professionally) are deemed to address a meaningful energy demand of the house. In this approach, different elements of the house (e.g. windows and roof) are integrated in a way that the whole building is assessed holistically.

Take the example below from our past experience, using this method:

Residence at Marengo

NatHERS rating with U2.7 windows (double glazed, thermally broken):

Residence at Berwick

NatHERS rating with U1.5 windows (triple glazed, thermally broken):

What are the PROS of VURB?

Reduction in construction costs (especially glazing):

Energy modelling tools account for heat stored or released from the ground:

The soil beneath the slab works like a thermal battery that stores and discharges heat from the house. Therefore, it has a great capacity to offset the heating or cooling demand of the house. Thermal mass is more accurately considered in VURB method. Hence, buildings with a slab on ground have a higher chance to have a cheaper construction cost with VURB.

Holistic integration of building zones and their fabrics and glazing:

Energy modelling tools allow for a more complex integration of building elements in energy balance, and hence the model may represent a deeper sense to obtain building energy demand. For example, solar heat gains from a large window can be transmitted inside the room and absorbed by the concrete slab with a high thermal mass. In the sun’s absence, the heat is then transformed back into the zone and offsets heating demand. Therefore, large north glazing, to a degree may be beneficial to some houses if the complex nature of the building fabric integration could be understood and undertaken. In our experience, buildings with large glazing to floor area ratios may gain better deals using VURB than the Star Rating method.

VURB model can be readily used for other assessments

With a little modification, VURB model can be used for daylight modelling where compliance with Part P2.4.4 Natural Light is required by the council. Also, with a VURB model, a CFD analysis can be undertaken for natural ventilation purposes and air movement assessments.

Best method to predict building’s heating & cooling demand in the design stage:

Determine the size of HVAC equipment and annual energy use:

Outcomes of energy modelling from VURB closely represents the actual energy demand of the Proposed Building. This information is useful to architects, builders and especially building services engineers. Once the HVAC equipment size is determined, it’s easier to locate their location with respect to the view, weight, and to estimate the overall cost of the HVAC system.

Undertake feasibility analysis for different energy source options:

Hour by hour heating and cooling demand of the proposed building is the key parameter to estimate what equipment or renewable option is most feasible for the building. It’s wise to consider referring to a professional feasibility assessment company that also undertakes VURB option for energy compliance. Once the Proposed Building is modelled and deemed to be compliant, the hour by hour results can also be used to determine what energy source option is the most suitable to meet the building demand.

Unlike NatHERS, Class 1b benefits from VURB method:

NatHERS Star Rating involves Class 1a, but VURB covers both Class 1a and Class 1b buildings.

Click here for further information on NCC building classification.

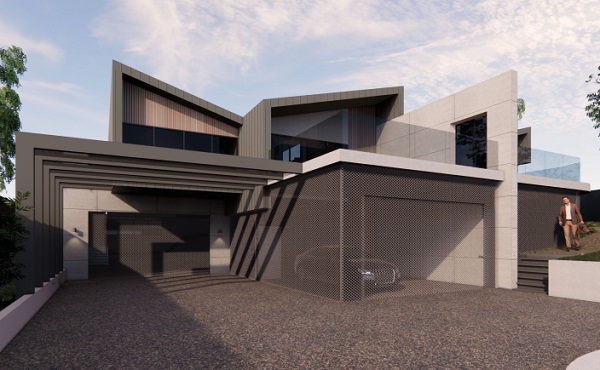

DISCOVER OUR PAST EXPERIENCE

Check out our past projects and see some complex buildings that the Energy Compliance Consultants has managed to satisfy its compliance.

What are the CONS of VURB?

VURB doesn’t cover Class 2 and Class 4 part of a building:

Only NatHERS star rating covers Class 2 and Class 4 buildings as there are no Elemental Provisions for energy compliance of Class 2 and Class 4 buildings in Section J.

VURB can’t be used to gain BESS energy points

When a Victorian council demands BESS best practice as an ESD initiative, points are awarded in case you go beyond a 6-star rating. Unlike JV3, VURB method can’t be used to achieve BESS energy efficiency points.

VURB is relatively more expensive to undertake:

3D modelling takes more effort than 2D modelling.

NatHERS accredited tools model the building in a two-dimensional form and also generate reports that are valid for submitting, but this is not the case under VURB. Accurate 3D modelling of a complex building takes much more effort and therefore relatively more expensive to undertake. However, construction cost reduction is usually more than the energy assessor fee.

What are NCC Reference Building requirements?

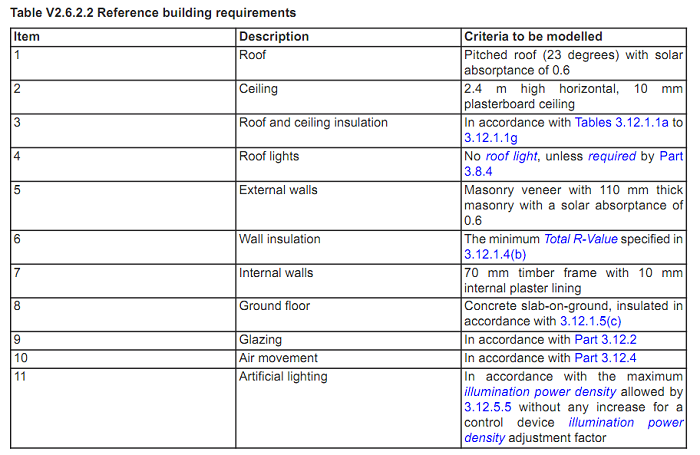

NCC Reference building is a building that has the same geometry of the proposed building but for the sake of energy modelling, NCC requires you to modify it as indicated below:

Reference Building roof

The Proposed Building can have a roof of any shape and material. However, NCC requires you to compare it to a standard roof that most average Australian houses have. Therefore, the NCC Reference Building should have a roof at 23 degrees with a solar heat absorptance value of 0.6.

Reference Building ceiling

The Proposed Building can have a ceiling with any height or a sloped cathedral ceiling for that matter. However, NCC requires you to compare it to a minimum ceiling height of 2.4m for a habitable room. This ceiling must also be flat to the exclusion of any cathedral ceiling.

Reference Building ground floor

The Proposed Building can have a suspended floor above ground floor level. However, NCC requires you to compare it to a building having a concrete slab on ground. Ground temperature fluctuation is lower than the ambient weather and relatively closer to the temperatures where people feel comfortable. This temperature stability together with a higher concrete thermal mass is the reason why NCC requires a comparison between Proposed Building and Reference Building having a concrete slab on ground.

Reference Building roof lights

The Proposed Building can have any number of roof lights. However, NCC requires you to compare it to a building having no roof lights. NCC Vol 2.0 Part 3.8.4 allows roof lights for habitable rooms with no or minimum means of daylighting. As roof lights add to the building cooling demand, NCC requires Proposed Buildings to have minimum to no roof lights.

FAQ

VURB is a verification method developed by the National Construction Code that allows for a compliance with energy efficiency requirements, using computer modelling. Buildings with complex geometries often face difficulties achieving compliance with the code, using regular methods like star-rating or DtS. In such instances, VURB often helps to achieve the compliance of external glazing with a lower cost compared to the regular methods. With VURB, you can have insulation added in excess of what’s required to part of the building (i.e. ceilings or under-slab) as a compensation the weaker performance of cheaper glazing. Impact of thermal mass, solar gain, thermal bridging, two-way heat transfer through a concrete slab on ground and several other features are better accounted for, using VURB method.

VURB is a method to comply with the energy efficiency requirements of NCC. This method is used in the following cases:

- To obtain a cost-effective energy compliance

- To obtain energy compliance when you can not achieve 6-star rating

- To obtain energy compliance for Class 1b building, that is not covered in 6-star rating using FR-5.

VURB is a verification method to achieve compliance under NCC Vol 2.0, Part 2.6, Performance Requirement P2.6.1. This involves compliance with the following:

- Part 3.12.1 (building fabric)

- Part 3.12.2 (external glazing and shading)

- Part 3.12.3 (building sealing)

- Part 3.12.4 (air movement)

Note that compliance with the above parts could be done using other methods such as DtS or Star Rating.

Here at Energy Compliance Consultants, we deliver our VURB reports between 4 to 7 days. This depends on the complexity of your building and the effort we put into our computer modelling.

For a VURB assessment to start, architectural drawings involving floor plan, roof plan, elevations, sections and window schedule shall be supplied to the assessor. In addition to that, client preferences and former 6-star assessment report also helps with a comprehensive VURB assessment.

No! VURB and star rating are both methods to achieve energy compliance with NCC. Therefore, there is no need to have a star rating before undertaking a VURB assessment. However, clients use our VURB services when star rating does not work in the favor of our clients due to high glazing costs or low achievable star rating. See our past experiences for more details.

VURB and JV3 are both verification methods of compliance with the energy efficiency requirements of NCC. The methods and are basically the same methods but applicable to different building classes . VURB is an alternative solution to achieve compliance under NCC Vol 2.0 Part 3.12 for Class 1 and Class 10 buildings. JV3 is an alternative solution to achieve compliance under NCC Vol 1.0 Section J for common parts of Class 2, Class 3 to Class 9 buildings.