How to evaluate heat loss from pipe

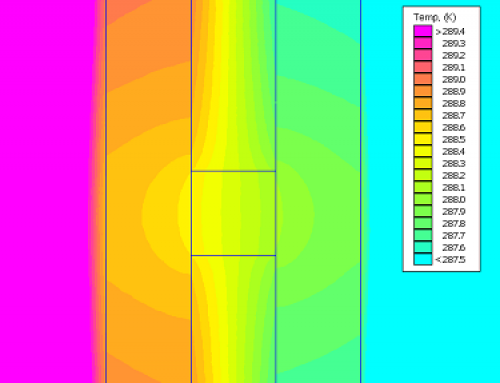

In following, h1 is the water thermal convection coefficient that varies with water velocity and turbulent regime inside the pipe. For heat loss from an existing hot pipe, we can ignore this. h4 is the most critical if the pipe has no insulation. H4 can vary from 5 to 40 W/m2K. h4 should also include the radiation heat loss from the pipe. Use the following example to see the calculation method.

in using the equation below, the dimension r1 and r4 should be in meters and for r3, r2 and r4 doesn’t matter as they are ratios.

Following is an example from Principles of Heat Transfer

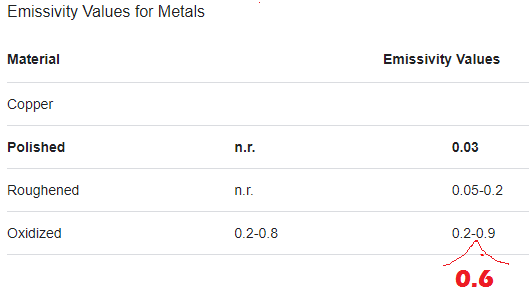

Radiation heat loss:

Note that heat loss from non reflective insulation or oxidised pipe surface (emissivity of 0.6) can account for up to 20% of total heat loss by convection. For pipe or insulation

Why do we wrap building?

Wall wraps minimize ingress from air, dirt and water to the inside of the house. Some allow moisture to move in and out and some block moisture. In tropical climates, we use moisture barriers to completely block the movement of moisture to the inside of the building. Most reflective insulations are not breathable and are moisture barriers that block the movement of moisture. Thesse are called c;lass 1 and 2 moisture barrier.For instance, FireSark is 97% reflective and is a class 2 vapour barrier that is bot breathable enough for cold climates.

in cold climates, where inside the house is warmer and more humid than outside (warm air can hold more humidity), we want to allow humidity to move outside the building. note that due to the moisture vapour pressure differential (higher inside, lower outside), moisture will move naturally to the outside of the building if we allow it with a breathable warp. Where humidity inside the building is more than outside, such as in Melbourne in winter, we want to remove humidity to the outside and condense it outside the insulation. Typical products for this application is vapour barrier. Class 3 to 4 vapour barrier is required for climate zones 6-8 [source: FireSark 97% reflective catalouge].

Reflective, breathable building wrap

Products like Ametalin SilverWrap are 97% reflective and are classified as a class 3 vapour barrier. Making it ideal for cold climates such as Melbourne. it is a Heavy Duty, Vapour Permeable wall wrap, designed for use in brick veneer and drained cavity wall systems to reduce the risk of condensation between wall layers. Classified as Class 3 Vapour Permeable, a dense pattern of micro-perforations allows water vapour to escape from the wall structure. it acts as a barrier to air, radiant heat and dust penetration. it is combustible but with low Flammability suitable for use in all BALs in bushfire-prone areas.

Class 4 is vapour permeable, air and water barrier membrane, it is light duty wall breather and not suitable for the ceiling. , non-reflective. It is installed in the exterior side if the building frame in zones 2 to 8. wall Cavity is needed for drainage and drying moisture transported out tf the building in winter.

Moisture barrier classes:

Referring to AS/NZS 4200.1:2017 “Pliable building membranes and underlays Part 1: Materials”, a moisture barrier is defined as a material or system that has a Moisture Vapour Transmission Rate (MVTR) of less than a certain value.

Class 1 : less than or equal to 0.1 grams per square meter per day such as sheet metal, polyethylene, and other impermeable materials.

Class 2 : less than or equal to 1 grams per square meter per day

Class 3 : less than or equal to 10 grams per square meter per day

Class 4 : Class 4 moisture barriers must be capable of withstanding high water pressures and have a minimum thickness of 1.5mm. They should also be resistant to ultraviolet (UV) radiation, chemicals, and microbial growth.

Bradford Moisture barrier products for wall and roof Enviroseal

this product can be used in all climates except climate zone 1 as it doesn’t block moisture travel from outside to the inside. We don’t recommend this product for roof as per manufacturer catalogue.

The foil in a Foil-faced blanket or any moisture, when positioned on the cold side of the construction, may increase the risk of condensation entrapment within the structure.

Enviroseal HTS is a class 4 Roof Sarking to allow vapour out and block water particles.

Thermoseal ResiWrap is a class 1 vapour barrier for roof

Poly air is vapour barrier with no classification.

How to insulate concrete walls?

One option is to add bulk insulation

Cheaper option is to add minimum 20mm furring channel and Ametalin SilverWrap as reflective and permeable insulation. The reflective insulation will need 20m to achieve R0.48 according to NCC 2019. In this example, condensation may occure on concrete wall depending on the concrete wall inside temperature. The bottom of the air cavity might need to be allowed to drain.

Insulation values from ICANZ

GHG emissions in NCC and GHG National Accounts

NCC 2019 uses outdated GHG emission values. For Victorian grid electricity for instance, NCC uses 1.168 kg/kWh and National Accounts 2021 uses 0.96 kg CO2-3/kWh. NCC 2019 should be used as reference in JV3 modelling until NCC2022 comes into effect.

pool room and water temperature and humidity

ASHRAE 4146 Rates of evaporation from swimming pools in active use provide a range for indoor pool water and room temperature and humidity:

How to install insulation around the slab perimeter?

With an in-slab or in-screed heating or cooling system, NCC requires insulation with an R-Value greater than or equal to 1.0, installed around the vertical edge of its perimeter.

Alternative to the above, the insulation can also be applied directly under the screed and above the structural concrete slab and on the edges of the screed:

Note that ASHRAE Standard 90.1 User manual (2013) doesn’t permit insulating the slab or screed as shown in graphic 6 below as it believes this detailed construction method is failed to be noticed (overlooked) in the field. If you are totally insulation the screed or slab sides and bottom, always do a double check and inspect the insulation placement before pouring concrete.

Modelling Unitary Systems for JV3 Assessment

In JV3 modelling, the most conservative approach, when no services data is for the AC system of the proposed building, our approach is as follows:

1- Refer to PMV analysis and assess the minimum heating and cooling capacity for each zone/space.

2- For reference building, use the bigger of each zone’s heating or cooling demand as that zones dedicated split system capacity. Assume a unitary single split system for each zone/space. Refer to MEPS and assess the COP of each zone. Calculate weighted average COP for reference and model the whole HVAC as a single system with weighted average COP. This results in higher COP for reference and it is more conservative.

3- For the Proposed building, use the bigger of each zone’s heating or cooling demand as that zones AC capacity. Assume a single central outdoor unit, i.e., a multi-split outdoor unit with a capacity equal to the total of all zones/spaces AC capacity. Refer to MEPS and assess COP of the outdoor unit.

3- Since no data is available on chiller variable efficiency with outdoor air temperature, we use the part load approach from Green Star modelling protocol with part load estimated from NCC Table J5.10a or J5.10b.