What are the Common Construction Elements?

Construction elements and their dimensions are crucial in building design. Typically, these elements vary in their:

- Type – frame, membrane,…

- Material – timber, metal,…

- Application – roof, wall,…

In this article, we look into the components of roof and wall construction, highlighting the most commonly used dimensions in Australia. We focus on these elements due to their role in thermal bridging and insulation allocation.

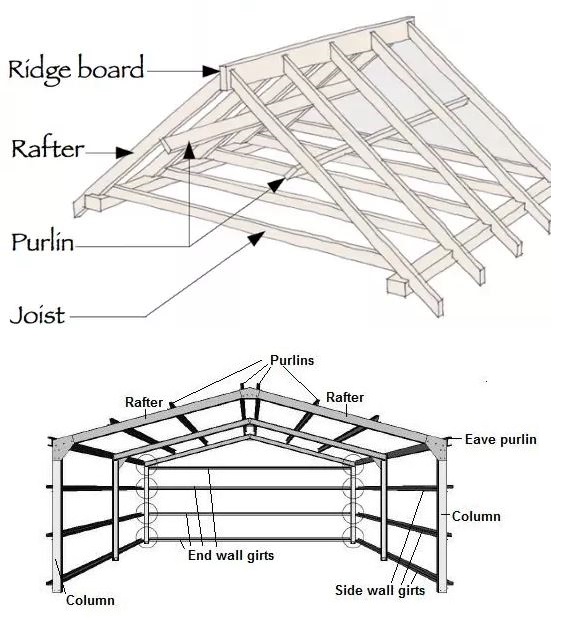

Roof Construction Elements

Purlin: the term purlin refers to roof members that are parallel to the walls or eaves. Purlins are required to support the roof sheeting or roof decking and themselves are supported by walls or rafters. The most commonly used steel purlins are Z-shaped 203×79×1.9mm. Purlins generally span from 1.2m to 8m. Insulation sits between purlins in a flat steel-framed roof system with an attached or suspended ceiling. This is typical of a Class 7b building with a conditioned space.

Rafter: the term rafter refers to a sloped structural member that extends from the roof ridge to the wall top plate. Rafters are designed to support the roof deck and its load. The most commonly used timber rafters are 240×35mm with 6000mm c/c. Insulation sits in the gap created by the timber rafters in a cathedral ceiling system.

Joist: the term joist refers to a horizontal structural member used in framing to span an open space. Generally, the longer face of a joist is positioned vertically. Depth of the joist is very important for a stable ceiling system. The wider the spacing between the joists, the deeper the joist will need to be to limit stress and deflection under load. The most commonly used timber joists are 90×35mm with 1200mm c/c. Insulation sits between the timber joists in a pitched roof with a flat ceiling system.

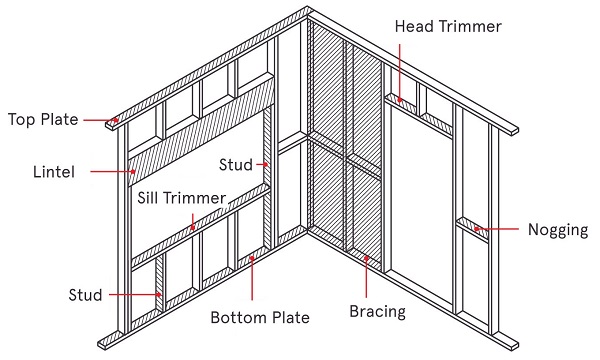

Wall Construction Elements

Stud: the term stud refers to a vertical framing member that is part of the wall construction. It is a fundamental element in frame building. Studs could be used just to separate spaces as non-load bearing studs. Studs shape the building envelope and hold windows and doors in place. The most commonly used timber stud wall dimension is 90×45mm @ 450mm or 600mm c/c. Steel framing studs are generally 92×35.5×0.75mm with 600mm c/c. Bulk insulation sits between the gap created by two adjacent studs.

Nogging: the term Nogging refers to a horizontal member of wall construction that runs in parallel with the top and bottom plates and between the studs. Noggings straighten the centre of the wall and provide lateral support to the studs. The number of noggings generally depends on the wall height. For a typical 2.7m high wall, one noggin is installed which contributes to the thermal bridging. Generally have the same size as the wall studs.

Purlins, Rafters and Thermal Performance of Buildings

Purlins, rafters and joists can potentially impact the energy efficiency and thermal performance of a building. When conducting Part J report, JV3 report or ESD report, energy assessors must ensure that thermal bridging through these construction elements is addressed. Energy efficiency reports involve achieving a required Total R-value for roofs, walls and floors. The contribution of purlins and rafters to reducing the Total R-value due to thermal bridging could be significant. Therefore, ESD consultants offer solutions to mitigate the negative effects of thermal bridging through purlins and rafters and to achieve the required Total R-value of building fabric at minimal cost.

Part J of NCC Volume 1, focuses on the energy efficiency of commercial buildings. To obtain a building permit, a Part J report (Section J report) is required for submission. For example, the Performance Requirement for a roof construction of an office in Melbourne, Victoria, is to achieve a Total R-value of 3.2. A typical uninsulated roof in Melbourne has a Total R-value of about 0.5. Does this mean that adding R2.7 insulation would achieve a Total R-value of 3.2, thus meeting the Performance Requirement of the code? the short answer is no. The reason is that the insulation does not actually add R2.7 to the roof. Since it is laid between roof purlins or rafters, thermal bridging reduces the effective R-value. Consequently, the combination of purlins and insulation achieves lower R-values, such as R2.0 or even R1.5.

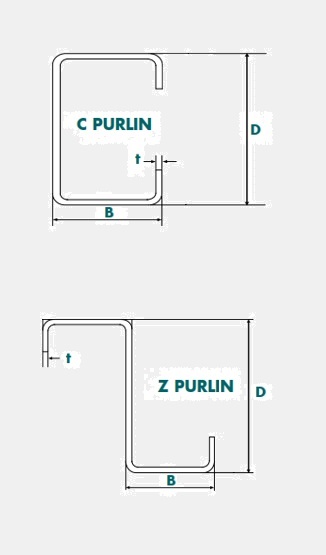

Typical Purlin and Rafter Sizes

The following table displays typical sizes of C-section and Z-section metal purlins and rafters used in Australia. Note that the lesser the depth and the greater the width and thickness, the more the purlin or rafter contributes to thermal bridging. These section details are used to account for thermal bridging while conducting Part J energy reports and JV3 reports.

| Section | Depth – mm (D) | Width – mm (B) | Thickness – mm (t) |

|---|---|---|---|

| 100-10 | 102 | Z: 53 – C: 51 | 1.0 |

| 100-12 | 102 | Z: 53 – C: 51 | 1.2 |

| 100-15 | 102 | Z: 53 – C: 51 | 1.5 |

| 100-19 | 102 | Z: 53 – C: 51 | 1.9 |

| 150-12 | 152 | Z: 65 – C: 64 | 1.2 |

| 150-15 | 152 | Z: 65 – C: 64 | 1.5 |

| 150-19 | 152 | Z: 65 – C: 64 | 1.9 |

| 200-15 | 203 | Z: 79 – C: 76 | 1.5 |

| 200-19 | 203 | Z: 79 – C: 76 | 1.9 |

| 200-24 | 203 | Z: 79 – C: 76 | 2.4 |

| 250-19 | 254 | Z: 79 – C: 76 | 1.9 |

| 250-24 | 254 | Z: 79 – C: 76 | 2.4 |

| 300-24 | 300 | Z: 100 – C: 96 | 2.4 |

| 300-30 | 300 | Z: 100 – C: 96 | 3.0 |

Performance Requirements for Purlins and Rafters

For a typical dwelling or townhouse, classified as a Class 1a building, adding a thermal break with a minimum R-value of R0.2 is sufficient to meet the Performance Requirements for mitigating thermal bridging. This is a common practice when conducting whether Residential Energy Report or VURB energy report.

For a non-residential building, the NCC requires calculating the Total R-value, including the effects of air gaps and thermal breaks. Unlike residential buildings, a thermal break with an R-value of R0.2 may not be sufficient to meet the Performance Requirements. After accurately calculating the Total R-value and accounting for thermal bridging, you will need to add sufficient insulation or thermal breaks to achieve the required Total R-value for the roof or ceiling.

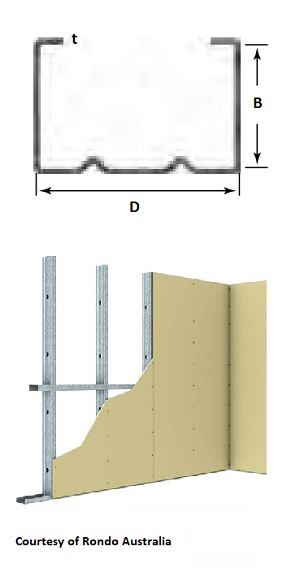

Typical Metal Stud Sizes

The following table displays typical metal stud sizes used in Australia. Note that the lesser the depth and the greater the width and thickness of the metal stud, the more it contributes to thermal bridging. These section details are used to account for thermal bridging while conducting ESD reports, Section J energy efficiency reports and JV3 Performance Solution Reports.

| Size | Depth – mm (D) | Width – mm (B) | Thickness – mm (t) |

|---|---|---|---|

| 50mm | 51 | 35.5 | 0.5 |

| 50mm | 51 | 35.5 | 0.75 |

| 65mm | 64 | 35.5 | 0.5 |

| 65mm | 64 | 35.5 | 0.75 |

| 65mm | 64 | 36.0 | 1.15 |

| 75mm | 76 | 35.5 | 0.55 |

| 75mm | 76 | 35.5 | 0.75 |

| 75mm | 76 | 36.0 | 1.15 |

| 90mm | 92 | 35.5 | 0.55 |

| 90mm | 92 | 35.5 | 0.75 |

| 90mm | 92 | 36.0 | 1.15 |

| 150mm | 150 | 35.5 | 0.75 |

| 150mm | 150 | 36.0 | 1.15 |

Performance Requirements for Metal Studs

For a typical residential dwelling (Class 1a building), adding a thermal break with a minimum R-value of R0.2 is sufficient to meet the Performance Requirements for mitigating thermal bridging.

For non-residential buildings, just like the case for roof and ceiling, you must calculate the impact of thermal bridging. After calculating the effective Total R-value (after reducing it to account for thermal bridging), you will need to add sufficient insulation or thermal breaks to achieve the required Total R-value.

FAQ

This section includes frequently asked questions about the impact of thermal bridging through metal elements, such as purlins, rafters, joists, studs and girts. This information is useful for builders and architects providing insight on how to address thermal bridging issues and find solutions before applying for a building permit. It also involves a basic understanding of the common construction materials used in Australia.

Rafters are sloped beams and run vertically from the ridge down to the eaves, whereas purlins are horizontal beams that are laid across rafters. Rafters form the main shape and framework of the roof and support roofing materials, however, purlins provide support for the rafters and distributes roof load evenly.

Rafters are sloped beams that support the weight and shape the framework of the roof, whereas joists are horizontal beams that are parallel to the ground. Joists provide support for floors and ceilings. Joists also support the rafters and tie them together and keep them from spreading under the weight of the roof.

Studs are vertical structural elements used in wall framing, however, girts are horizontal structural members used in wall framing and are attached to the columns or studs. While studs could be non-bearing, the girts provide lateral support to the wall cladding and internal finish. They also provide resistance to wind loads.

Battens are narrow strips of material that are often made of woods. These elements are used beneath the roof cladding and over the main roof frames to provide a fixing point for roofing materials. Battens create an air gap that helps with the reduction of thermal bridging, condensation control and addition of roofing blankets. They are sometimes offered as a solution to improve the performance of the roof by ESD consultants in their Part J or performance solution reports.

A furring channel that is also known as hat channel or top hat, is a metal framing element that is used to level surface for the attachment of insulation and wall finish. They also create an air gap that reduces thermal bridging and allow for a reflective insulation to work properly. Furring channels also provide resistance to condensation. These elements improve the energy efficiency performance of walls and ceilings and are proposed as solutions in ESD or JV3 performance solution reports. The most commonly used furring channel size in Australia is 28mm x 38mm (depth x width).

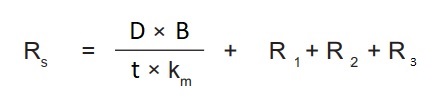

To calculate thermal bridging in purlins and rafters, use the following formula to calculate thermal resistance of the metal section:

Where:

Rs = thermal resistance of purlin or girt (m2.K/W)

D= flange depth (m)

B= flange width (m)

t= flange thickness (m)

km= thermal conductivity of metal, 47.5 W/m.k in case of steel

R1, R2= contact resistances between the steel element and the upper and lower side, 0 m2.K/W in case of full contact, 0.03 m2.K/W in case of loose contact

R3= thermal resistance of air gap (if available) on the upper side or lower side of the steel element, 0.17 m2.K/W in case of 20mm non-reflective air gap

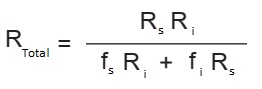

Knowing the thermal resistance of the insulation (Ri) that is added between purlins or rafters, and the fraction of insulation (fi) and metal section (fs), Total R-value of the roof (Rtotal) could be calculated using the formula below:

The negative effect of thermal bridging on the added insulation value can be calculated by subtracting the Total R-value from the insulation R-value.

The Performance Requirements for metal stud walls and girts differ between residential buildings and non-residential buildings.

For residential buildings, NCC requires you to add no less that R0.2 thermal break to be installed at all points of contact between the external cladding and the metal frame. This is the case even if you are following the Verification Method for energy efficiency compliance instead of Deemed to Satisfy pathway [1]

For non-residential building, you need to calculate the effective Total R-value that includes the negative impact of thermal bridging. The effective Total R-value must be not less than the required Total R-value and if it is, you need to tackle the problem by adding air gaps and thermal breaks.

The Performance Requirements for purlins and rafters differ between residential buildings and non-residential buildings.

For residential dwellings, NCC requires adding R0.2 thermal break to be installed between the metal sheet roofing and its supporting metal purlins, metal rafters or metal battens. This is the case even if you are following the VURB Method instead of DTS method for energy compliance [1]

For non-residential building, you need to calculate the effective Total R-value that includes the negative impact of thermal bridging caused by metal purlins and rafters. The effective Total R-value must be not less than the required Total R-value.

For residential dwellings, NCC Vol 2.0 does impose any requirements for timber studs and rafters. While timber studs and rafters do contribute to thermal bridging to some extent, the NCC considers this impact as negligible.

For non-residential buildings, NCC Vol 1.0 requires assessors to calculate the negative impact of thermal bridging and determine the effective Total R-value for timber-framed walls and ceilings. The calculated effective Total R-value must meet or exceed the required R-value by the NCC.